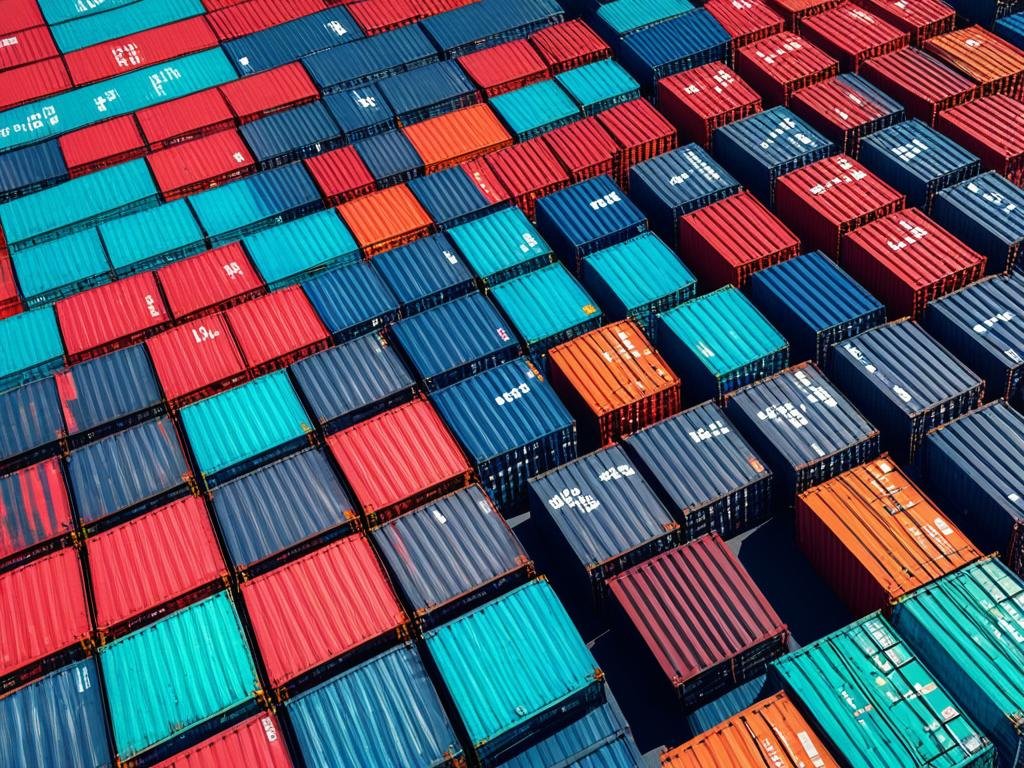

Hi, I’m here to help you understand the cost of shipping containers and how it can impact your logistics operations. When it comes to shipping goods, it’s crucial to have a clear understanding of container prices to effectively manage your budget and optimize your supply chain.

There are several factors that influence the cost of shipping containers. These include the type and size of the container, the distance and route of shipment, and the availability of the desired container. By knowing these factors and exploring the different types of containers, you can make informed decisions that will benefit your business.

Whether you’re a business owner or a freight forwarder, this guide will provide valuable insights into shipping container prices and how to reduce costs. Let’s dive in and discover the world of container pricing!

Key Takeaways:

- Shipping container prices can vary depending on factors such as container type, size, distance of shipment, and availability.

- Understanding the different types of shipping containers, including standard dry containers, refrigerated containers, open top containers, and flat rack containers, is essential for making informed decisions.

- Factors affecting shipping container costs include container size, container type, distance of shipment, and the availability of desired containers in specific regions.

- The cost components of a shipping container include freight charges, port charges, and insurance costs.

- To reduce shipping container costs, consider strategies such as consolidating shipments, utilizing intermodal transport options, and negotiating with carriers.

Types of Shipping Containers

When it comes to shipping goods, choosing the right container is crucial to ensure the safe and efficient transport of your cargo. There are four common types of shipping containers that cater to different cargo requirements:

Standard Dry Containers

The most widely used type of shipping container is the standard dry container. These containers are constructed from durable steel and come in various sizes, including 20 feet and 40 feet. Standard dry containers are suitable for transporting a wide range of goods, from dry goods to machinery and equipment.

Refrigerated Containers (Reefers)

Reefer containers are designed to maintain specific temperatures and humidity levels, allowing for the transportation of perishable goods such as fruits, vegetables, pharmaceuticals, and dairy products. These containers have built-in refrigeration units that can provide both cooling and heating options to preserve the quality and freshness of the cargo throughout the journey.

Open Top Containers

For cargo that exceeds the height limitations of standard containers, open top containers are the ideal choice. These containers have a removable top that allows for easy loading and unloading of oversized cargo, such as machinery, vehicles, and construction materials. The open top design provides greater flexibility in terms of cargo dimensions and makes it easier to secure and fasten the cargo during transport.

Flat Rack Containers

Flat rack containers are specifically designed for transporting oversized and bulky cargo that cannot fit into standard containers. These containers have collapsible sides and no roof, allowing for easy loading and unloading of items such as large machinery, heavy equipment, and pipes. Flat rack containers provide excellent stability and security for irregularly shaped cargo.

Choosing the right container type is essential to ensure the safety and security of your goods during transportation. Consider the nature and dimensions of your cargo when selecting a container type, and consult with freight forwarders or logistics experts for guidance if needed.

Take a look at the image below to get a better understanding of the different shipping container types:

Factors Affecting Shipping Container Costs

When it comes to shipping container costs, several factors come into play. It’s essential to consider these factors to accurately budget for your shipping needs. Let’s take a closer look at the main influencers:

When it comes to shipping container costs, several factors come into play. It’s essential to consider these factors to accurately budget for your shipping needs. Let’s take a closer look at the main influencers:

- Container Size:

- Container Type:

- Distance of Shipment:

- Availability:

First, the size of the container affects its price. Larger containers generally come with higher costs due to their increased capacity and fitting requirements. Specialized containers designed to transport specific goods or equipment may also have higher price tags.

Next, the type of container you choose can impact the overall cost. Refrigerated containers, for instance, are equipped with cooling systems to transport perishable goods. These specialized containers usually command higher prices compared to standard dry containers.

The distance of shipment is another consideration. Longer distances and certain routes can result in additional fees, such as fuel surcharges or tolls. Planning for these extra costs is crucial to avoid budget overruns.

Lastly, availability plays a role in container pricing. The demand and supply dynamics in specific regions can affect container prices. If the desired container is scarce or in high demand, the price may be higher.

Example:

“We had to ship a large quantity of fragile goods from New York to Los Angeles, and finding the right container proved to be a challenge. The availability of specialized containers suitable for fragile items was limited, and we had to pay a premium price to secure the necessary containers. It’s important to plan ahead and consider availability when budgeting for shipping container costs.” – John Smith, Logistics Manager

Understanding these factors and their implications on shipping container costs allows businesses to make informed decisions and optimize their logistics operations. It’s crucial to weigh these factors against your specific needs and budget to ensure a cost-effective shipping solution.

Cost Components of a Shipping Container

When it comes to shipping containers, understanding the cost breakdown is crucial for effective budget management. The overall cost of a shipping container can be categorized into three main components: freight charges, port charges, and insurance costs.

When it comes to shipping containers, understanding the cost breakdown is crucial for effective budget management. The overall cost of a shipping container can be categorized into three main components: freight charges, port charges, and insurance costs.

Freight Charges

Freight charges are the fees paid to carriers for the transportation of goods. These charges are based on various factors such as the weight and dimensions of the cargo, the distance of shipment, and the mode of transport. It’s important to work with reputable carriers who offer competitive rates and reliable services.

Port Charges

Port charges encompass handling and processing fees incurred at both the origin and destination ports. These charges cover services such as loading and unloading of containers, customs clearance, and documentation. The specific charges may vary depending on the port and the services required.

Insurance Costs

Insurance costs play a crucial role in protecting your goods during transit. It is essential to have appropriate cargo insurance to safeguard against potential risks such as theft, damage, or loss. Premiums for insurance coverage typically depend on the value of the cargo, the mode of transport, and the shipping route.

Understanding these cost components will help you manage your overall shipping budget more effectively. By analyzing freight charges, port charges, and insurance costs, you can identify areas for optimization and make informed decisions to drive cost savings.

| Cost Component | Description |

|---|---|

| Freight Charges | Fees paid to carriers for transporting goods. |

| Port Charges | Handling and processing fees at origin and destination ports. |

| Insurance Costs | Protection for goods during transit. |

By considering these cost components and optimizing each aspect, you can achieve greater efficiency and cost-effectiveness in your shipping container operations.

Ways to Reduce Shipping Container Costs

When it comes to optimizing logistics operations, finding ways to reduce shipping container costs is crucial. By implementing the right strategies, businesses and freight forwarders can save money while maintaining efficient shipping processes. Here are some effective ways to achieve cost savings in container transportation:

When it comes to optimizing logistics operations, finding ways to reduce shipping container costs is crucial. By implementing the right strategies, businesses and freight forwarders can save money while maintaining efficient shipping processes. Here are some effective ways to achieve cost savings in container transportation:

1. Consolidation of Shipments

Consolidating shipments can help optimize load capacity and reduce transportation expenses. By combining multiple smaller shipments into a single container, businesses can take advantage of economies of scale, reducing per-unit transportation costs. This also minimizes the overall number of containers used, which can result in significant cost savings.

2. Utilizing Intermodal Transport

Intermodal transport, which involves using multiple modes of transportation, such as rail or barge in addition to trucks, offers cost savings and increased efficiency. By leveraging intermodal options, businesses can reduce reliance on long-haul trucking, which can be more expensive. Rail or barge transport is often more economical for long-distance shipments, allowing for reduced container costs.

3. Negotiating with Carriers

Negotiating with carriers for better rates and terms is another effective strategy to lower container costs. By leveraging the volume of shipments and establishing long-term partnerships, businesses can secure more favorable pricing. Negotiations can also include discussing flexible payment options or alternative routing arrangements, helping to further reduce shipping expenses.

4. Choosing an Experienced Freight Forwarder

Partnering with an experienced freight forwarder who understands your unique requirements can significantly streamline operations and reduce container costs. A knowledgeable forwarder can provide invaluable insights into optimizing container utilization, selecting the most cost-effective routes, and navigating complex international shipping regulations. Their expertise can help you make informed decisions and identify additional cost-saving opportunities.

By implementing these strategies and exploring innovative solutions, businesses can successfully reduce shipping container costs without compromising on the quality and efficiency of their logistics operations. It’s essential to continuously evaluate and refine your container management approach to adapt to changing market conditions and seize cost-saving opportunities.

Conclusion

Understanding the cost of shipping containers is crucial for effective container cost management in logistics operations. By considering factors such as container type, size, distance of shipment, and availability, businesses and individuals can make informed decisions to optimize container costs.

Implementing strategies like shipment consolidation, intermodal transport, and negotiations with carriers can significantly reduce shipping container expenses. Consolidating shipments maximizes load capacity and minimizes transportation costs. Utilizing intermodal transport options, such as rail or barge, offers cost savings and increased efficiency. Negotiating with carriers for better rates and terms further lowers container costs.

It is important to choose a reliable freight forwarder who can provide cost-effective container solutions tailored to specific needs. With their expertise, businesses can manage container costs effectively and ensure a streamlined logistics operation.

FAQ

What are the different types of shipping containers?

The different types of shipping containers include standard dry containers, refrigerated containers (reefers), open top containers, and flat rack containers.

What factors affect shipping container costs?

The factors that affect shipping container costs include the size and type of the container, the distance and route of shipment, and the availability of the desired container.

How can I break down the cost of a shipping container?

The cost of a shipping container can be broken down into three main components: freight charges, port charges, and insurance costs.

What are some ways to reduce shipping container costs?

Some ways to reduce shipping container costs include consolidating shipments, utilizing intermodal transport options, negotiating with carriers for better rates, and choosing an experienced freight forwarder.